Price 70 आईएनआर/ Square Foot

Specification

- रासायनिक नाम

- कैस नं

- -

- टाइप करें

- Heavy Duty Flooring Service

- स्टैण्डर्ड

- Industrial

- ग्रेड

- Premium

- उपयोग

- दिखावट

- भौतिक रूप

- पैक का आकार

- Customized as per Project Requirement

- पैक टाइप

- On-Site Application

Trade Information

- Minimum Order Quantity

- 2000 Square Foots

- नमूना नीति

- मुख्य घरेलू बाज़ार

About

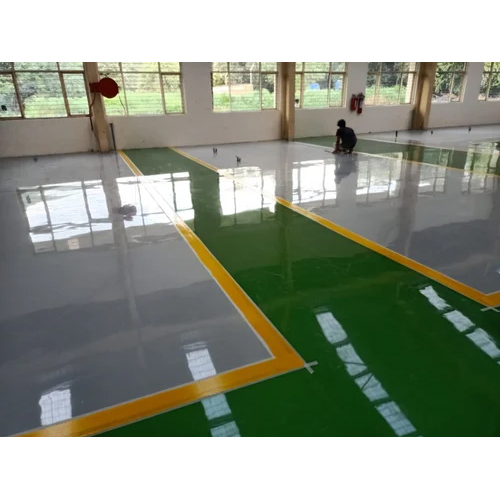

When it comes to flooring options, epoxy flooring, including epoxy grout has gained immense popularity due to its durability, versatility, and aesthetic appeal. Epoxy flooring is a type of surface coating that is made by mixing resin and hardener, creating a strong, seamless, and glossy finish. Whether you are looking to enhance the look of your home, office, or industrial space, epoxy flooring offers a wide range of benefits and options to suit your needs. In this comprehensive guide, we will understand what is epoxy flooring, explore its types, benefits, and how to choose the ideal epoxy flooring for your space.

| Available Flooring Type | TRIMIX |

| Usage/Application | Indoor |

| Features | heavy duty |

| Location Served | all over India |

| Flooring Type | trimix |

| Provide सेवाएं In | industrial |

2 mm Epoxy Floor Coating

Step 1 : Floor Prepration

Step 2 : Applying Primer Coating

Step 2 : Applying Scred Coat 1mm

Step 3 : Applying Top coat 1 mm

Heavy-duty flooring services are designed to provide robust and durable flooring solutions for industrial and commercial environments. These services typically involve the installation of flooring materials that can withstand heavy loads, frequent foot traffic, spills, and other stressors common in such settings.

Key Features of Heavy-Duty Flooring:

-

Durability: Engineered to last, withstanding wear and tear over time.

-

Load-Bearing Capacity: Capable of supporting significant weight without damage.

-

Ease of Maintenance: Easy to clean and maintain, ensuring safety and reducing downtime.

-

Chemical Resistance: Resistant to spills of chemicals or oils, crucial for industrial environments.

-

Safety Features: Often slip-resistant to enhance worker safety.

Common Types of Heavy-Duty Flooring:

-

Heavy Duty Vinyl Flooring: Durable, easy to clean, and versatile.

-

Heavy Duty Rubber Flooring: Ideal for impact absorption and noise reduction.

-

Heavy Duty Wood Flooring: Offers a natural look and feel, suitable for offices or customer-facing areas.

-

Heavy Duty Industrial Floor Mats: Provides extra traction and is easy to replace.

-

Heavy Duty Shop Flooring:

-

3 MM EPOXY FLOOR COATING

Step 1: Surface preparation by mechanical means: Grinding of floor whichever suitable depending on surface.

Step 2 : Applying one coat of primer.

Step 3 : Applying 2mm Screed coat .

Step 4: Applying 1 mm Epoxy Top Coat in any color finish.

Premium Strength and Customization

Our heavy duty flooring stands out for its robust compressive strength, customizable thickness, and superior resistance to chemicals and abrasion. Applied using specialized trowel or mechanical finishing methods, this service can be tailored to meet specific site demands and traffic conditions. The smooth or anti-skid finish options and wide color palette ensure both safety and aesthetic alignment.

Project-Based, Efficient Installation

Each flooring project is managed with precision, from substrate preparation to on-site application, ensuring smooth workflows and rapid curing. Clients benefit from flexible pack sizes and a service model suited for both new installations and upgrades in industrial or commercial spaces. Surfaces are ready for use within 24-48 hours, minimizing downtime across PAN India.

FAQs of Heavy Duty Flooring Service:

Q: How is the heavy duty flooring applied and what methods are used?

A: The flooring is installed using either trowel finishing or mechanical finishing techniques, depending on the site requirements. Both methods ensure optimal surface smoothness or anti-skid properties as specified by the client.Q: What types of surfaces are suitable for this flooring solution?

A: This service is suitable for concrete and prepared base floors, commonly found in industrial and commercial environments. Our product offers excellent adhesion, ensuring long-term durability on compatible substrates.Q: What level of resistance does the flooring offer against chemicals and abrasion?

A: The flooring is engineered with high chemical and abrasion resistance, making it ideal for environments exposed to corrosive agents or heavy wear, such as factories, warehouses, and high-traffic commercial areas.Q: When can the newly installed flooring be used after application?

A: The curing process typically takes between 24 and 48 hours. Once cured, the flooring is ready to withstand heavy duty operations and foot traffic.Q: Where is the service available and do you cover PAN India locations?

A: Yes, our heavy duty flooring service is available across PAN India. We cater to industrial and commercial clients everywhere in the country, providing on-site application by skilled technicians.Q: What are the main benefits of choosing this service for high traffic areas?

A: Clients benefit from a premium-grade, industrial-standard flooring solution that offers excellent compressive strength, superior chemical and abrasion resistance, customizable appearance, and optimal slip resistance. These features collectively enhance safety, longevity, and operational efficiency.Q: Can the flooring thickness and finish be customized according to project requirements?

A: Absolutely. We offer customizable thickness from 5 to 10 mm and a choice between smooth and anti-skid finishes. The final specification is tailored to each projects traffic, safety, and visual requirements.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें